Tugs and Offshore Supply Vessels – Non Z-Drive

ATB Tugs

LamaLo has conducted shafting alignment and vibration analysis and measurements on over 30 new build ATB Tugs and continues to work on more vessels of this Type each year. Work includes theoretical alignment and lateral (whirling) vibration analysis and measurements. All vessels that LLT has worked on during construction have operated without incident. Troubleshooting work is also conducted each year on other vessels.

|

MV Harvey War Horse

(2 x 5,000 HP)

MV Harvey War Horse II was constructed by Eastern Shipbuilding Group. The vessel has an overall length of 145' and has a twin screw propulsion configuration. Each of the 4 bladed fixed pitch propellers is directly driven by a diesel engine, with a rating of 5000 HP at 900 RPM, through a single reduction reversible gearbox. The propulsion shaft is approximately 49' long, and is supported by a strut and sterntube bearing. The main gear shaft is supported by two bearings. LamaLo Technology Inc. (LLT) was contracted by Eastern Shipbuilding Group to assist with the propulsion shaft alignment. LLT conducted a theoretical alignment and a lateral (whirling) vibration analysis, and provided final alignment using the strain gauge technique.

MV Seabulk Luanda

|

MV Julia

(2 x 3,505 HP)

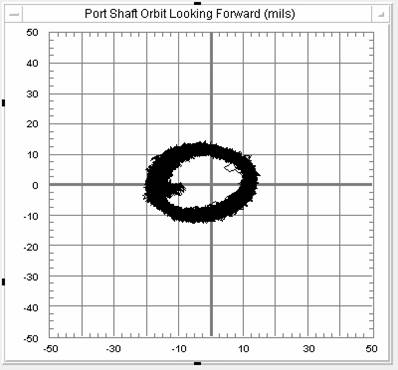

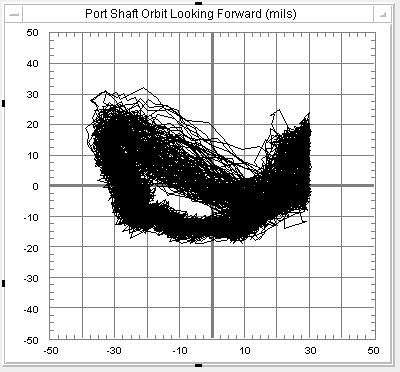

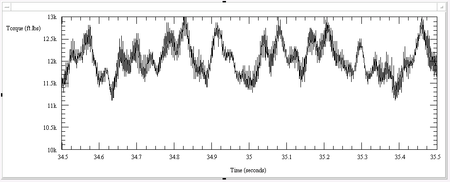

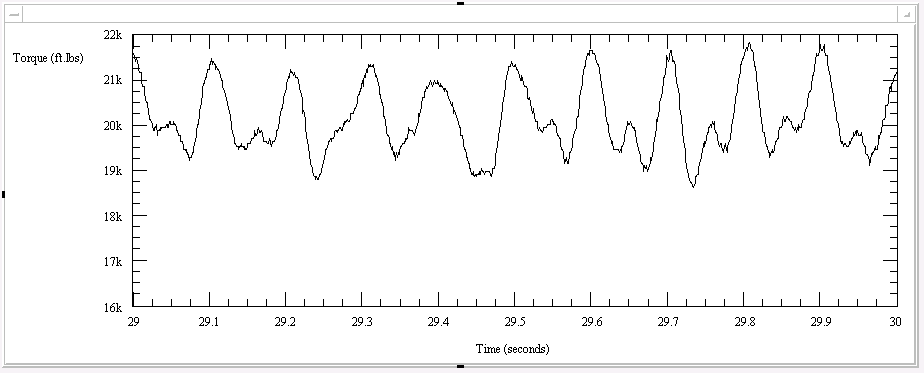

The MV Julia is a 120' twin screw Tug that was delivered in 1998. Each of the 5 bladed fixed pitch propellers is directly driven by a diesel engine, with a rating of 3505 HP at 900 RPM, through a single reduction reversible gearbox. The propulsion shaft is approximately 35' long, and is supported by a strut and a sterntube bearing. The main gear shaft is supported by two bearings. High shaft vibrations were reported on this class of vessel shortly after delivery and damage/failure of the propeller shafting occurred. The propeller shafts were then replaced with higher strength shafts, and the vessel ran without incidence until 2006 when a broken pinion tooth on the starboard gearbox was detected and scuffing of pinion teeth was observed on the port pinion teeth. Both port and starboard pinions were replaced and the starboard bull gear was replaced. LamaLo Technology Inc. was contracted to investigate the source of the pinion failure, conduct a theoretical finite element analysis of the alignment and whirling characteristics of the shaftline and assess the design arrangement. Strain gauge alignment measurements and analysis were also conducted. Recommendations for realignment were provided.

MV Joy Anne Keller

|

MV Seabulk Vung Tau Class

(2 x 2,540 kW)

The MV Seabulk Vung Tau, a 63m Anchor Handling Supply (AHS) vessel, is under construction at Labroy Shipyards in Batam, Indonesia. The vessel is a first of four “E” class vessels. It has a twin screw propeller configuration. Each of the 4 bladed controllable pitch nozzled propellers is directly driven by a diesel engine with a rated power of 2,540 kW at 750 RPM, through a single reduction gearbox. To reduce the risk of propulsion shafting problems LamaLo Technology Inc. (LLT) was contracted by Seabulk International Inc. to provide an independent theoretical shafting alignment analysis, to review the design arrangement, and to provide strain gauge alignment analysis.

MV Venture Sea

|

|

High Frequency Vibration Present (250 to 300 Hz)

Noise from Propeller Singing No High Frequency Vibration

No Noise |

MV Pionero

|

Seacor Vision and Vantage - AHTS

(2 x 4,580 HP)

Propulsion System Failure Investigation. Determined cause of failure of machinery components and least-cost solution. This included measurement of the propulsion shaft axial, lateral and torsional vibration characteristics and the alignment condition. Repair and re-alignment work was done on the Seacor Vantage in the winter of 1999/2000. The Seacor Vision re-alignment was conducted in the fall of 2000. After this work, measurements on the vessels indicated acceptable alignment and vibrations. The vessels have been operating since with not further propulsion shafting failures.

|

Unloaded Roller Bearing - Acceptable Vibrations

Loaded Roller Bearing - Acceptable Vibration

|

Seacor Gerard Jordan and Vanguard – AHTS

|